We meet the budding knitwear innovators as they open their first pop-up shop in Covent Garden

Who? Kirsty Emery, Ben Alun-Jones and Hal Watts are three Royal College of Art graduates and the founders of Unmade: a studio that creates bespoke knitwear co-designed by customers. By using computer-programmed industrial knitting machines, Unmade encourages their audience to manipulate and ‘unmake’ the patterns and colourways of their Merino wool designs online; from the contours of a 1930s map of Borneo, designed in collaboration with Christopher Raeburn, to the uniformity of a houndstooth print, generated by the Amsterdam-based design studio, Moniker.

Industrial design graduates Alun-Jones and Watts considered the possibilities of machine-produced bespoke knitwear while consulting for the United Kingdom Olympic Team in 2012. "We were thinking about custom fitted knitwear that would make athletes more aerodynamic," Watts explains. "At the time, it was impossible because it can take an expert two days to set up a single knitting pattern on a machine... But working with Emery, who studied Fashion Knitwear, we’ve spent two years developing a more intelligent way to control them."

A manufacture motivated interpretation of couture, Unmade can produce one-off garments, instead of working to the usual commercial minimums of 110 units. Their innovative approach to technology is synonymous with British knitwear history: John Smedley operates from Lea Mills, the oldest mill in the world in production, and are pivotal figures of the industrial revolution, Scottish fashion designer Bill Gibb worked with Gould’s in Leicester to create complex knitwear designs thought only achievable by hand, and more recently Pringle of Scotland collaborated with the material scientist Richard Beckett to create cable knit jumpers interwoven with 3D printed nylon fibres for their A/W14 collection.

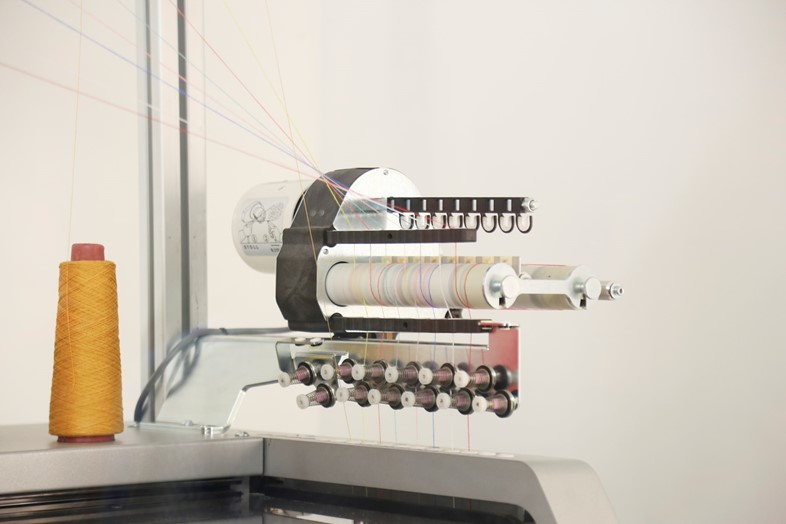

What? Unmade operate three German Stoll knitting machines from their Somerset House studio location, and one from their Covent Garden pop up shop. Affectionately called Herman, Helga, Hansel and Gretel, their names recall associations between knitting and handwork, an activity that was encouraged during the Arts and Crafts Movement of the 1880s. Stolls produce 10% of the entire world’s clothing, and the hardware of Unmade’s machines remains unchanged, but operates using new pattern generating software. The ubiquity of the Stoll means that Unmade can run mini factories by programming machines from anywhere in the world, reducing their own carbon footprint alongside shipping costs and delivery times for their customer.

"Jacquard knits can come out in completely different sizes depending on the detail of a pattern," says Watts of their software development process. "A 300 by 300 stitch knit varies in size depending if it is plain or patterned, so we had work with a team of physicists to make up mathematical models that could predict the sizes of a garment, and then adjust all of the tensions on the machines to ensure they were knitted in the correct size."

Why? Unmade encourage a creative dialogue between designers and customers, working with a range of creatives including agency Studio Moross and illustrator Malika Favre, to design knitwear patterns that be then be reimagined by its audience. "Christopher Raeburn had previously done a project where you could choose a section of recycled parachute to cut a jacket from," explains Alun-Jones on collaborating with the London-based fashion designer. "We wanted to work with people who had an interdisciplinary approach and were looking at how to involve an audience in what they were doing."

"I wanted my work to be a celebration of the translation from digital to material," says digital artist Nicolas Sassoon, who has created animated GIFs for Kenzo, and whose pixel focused creations translated fluidly into the detailed stitch by stich requirements of Unmade’s knitwear design software, likened by Alun-Jones to a Photoshop Paintbrush tool. "I don’t always agree with the production process of garment making," Sassoon adds. "But with Unmade it becomes a highlight."

Unmade have a zero stock approach to retail, only producing garments once they have been created and bought online. With a focus on sustainability they have zero wastage, and buy single rolls of yarn from Zegna Barrufa Mill in Italy only when they need it. "Whether we make five jumpers or 500, our production cost is identical," explains Emery. The studio also allows burgeoning designers to take advantage of machine knitted processes previously inaccessible due to volume specifications, and could see their collaborators selling their knitwear designs immediately after they have appeared on the catwalks.

Hand knitting has strong symbolic associations with narrative; the rhythmic clink of knitting needles creating a garment over time echoing the tonal lilts of oral storytelling. An Unmade jumper takes a mere ninety minutes to create, but Emery, Alun-Jones and Watts uphold this narrative tradition, finishing their knitwear by hand with labels that intercross the name of the studio and collaborator, a personalised name label and a history of the knitwear pattern that is unique to its creator.

Unmade’s pop-up shop in Covent Garden, London is open until December 24, 2015