When Makiko Minagawa first met Issey Miyake in 1970, it was on the premise of getting his advice on her planned move to London – but their interaction didn't quite go as planned. "We met and he said, 'forget London and come and work with me,'" she recalls, "so I did... and I've never looked back." Their relationship ever since has been mutually fortuitous: over the past four decades, Minagawa has worked as Miyake's textile designer, but when in 2000 she decided she wanted to establish her own label, HaaT, he supported her decision. In fact, HaaT now sits neatly under the Miyake brand umbrella, and is specifically dedicated to pushing the boundaries of textile design: employing craftsmanship, traditional methods and hand-made fabrications to create pieces that unite heritage techniques with modern manufacturing. Each garment is meticulously crafted, endures 50 hours of studio wear to test its practicality, and is then finished with utmost precision; as Minagawa explains, "Finishing touches are important – they are the process which adds the final detail to the textile."

Not only is every element of HaaT's clothing is carefully considered, but so too are the methods which go into making the pieces. "It is important to work with and place orders with the factories you like and wish to support," says Minagawa, whose dedication to preserving heritage Japanese artistry is (literally) part of her DNA: her grandfather used to hand-dye silk kimonos, and her father designed textiles for Japanese fabric screens. This dedication is now realised in her garments, which she is determined will preserve the "warmth of the creators’ hands," engaging artisans to consistently push the boundaries of fabric design. Here, we speak to the renowned designer about the very meaning of HaaT, and the elaborate techniques she has most recently discovered...

On establishing HaaT...

"A trip to India in 1983 made a big impact on me: I saw the refined techniques of craftsmen, their detailed handwork, and the protection measures enforced by the Indian government. At the time, Japan was in the midst of economic growth, with the industrialisation of mass production progressing; production areas throughout Japan were busy at work, and so I experienced no difficulties creating all sorts of materials. I also handled synthetic fibres and found joy in creating items through mass production. However, I did not want to forget the beauty and appeal of natural materials and methods. In around 2000, when it was becoming increasingly difficult to make materials by hand in Japan, I felt that we could create textiles where one could feel the warmth of the creators’ hands, even with machine weaving, by making ingenious changes to production techniques and processes. I hoped to create clothing mostly from natural materials by making one trial product after another at factories, searching for raw materials, and collaborating with craftsmen who have rare traditional skills. The result was HaaT."

On naming 'HaaT'...

"For the items that are made in Japan, HaaT is derived from the English word ‘Heart’. For the items that are made in India, HaaTH comes from the Hindu word meaning ‘hand’, and ‘handcraft’. Thus, the brand name HaaT comes from both of these words. HaaT also means ‘market’ in Hindu; a place where everyone gathers."

On where traditional techniques meeting modern ones...

"This season, we used 40-count linen yarn for the warp and weft of some of the pieces. The linen fabric, made to be a flexible process, is then dyed with a traditional Japanese deep black dyeing Montsuki technique. The yellow circles that look like full moons are dyed using the same dyeing technique that is applied to traditional Japanese family crests, using Itajime resist tie-dyeing. The two-tone base is sewed tightly in the middle and the yellow part is covered, so when dyed, the Montsuki black does not reach the yellow part."

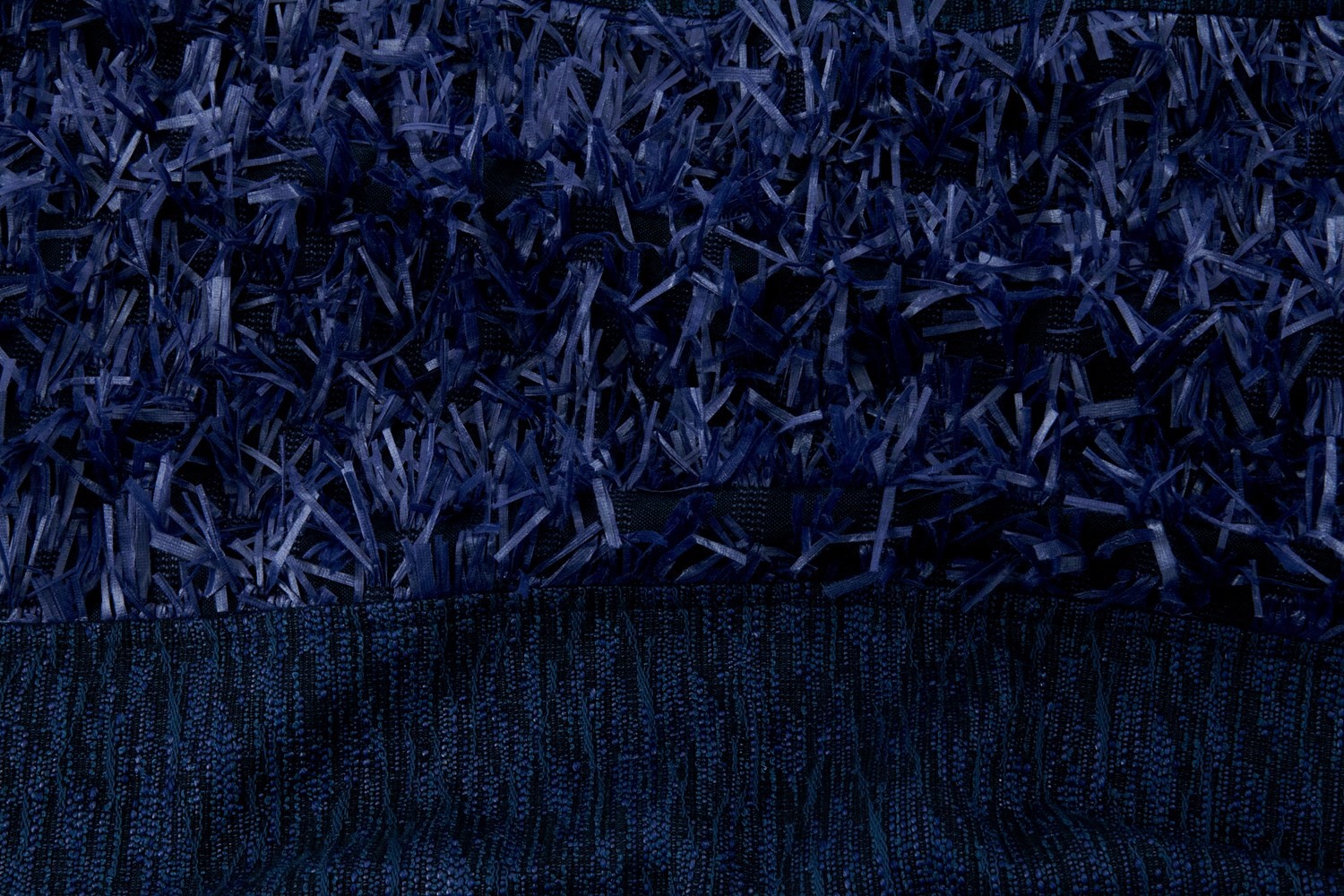

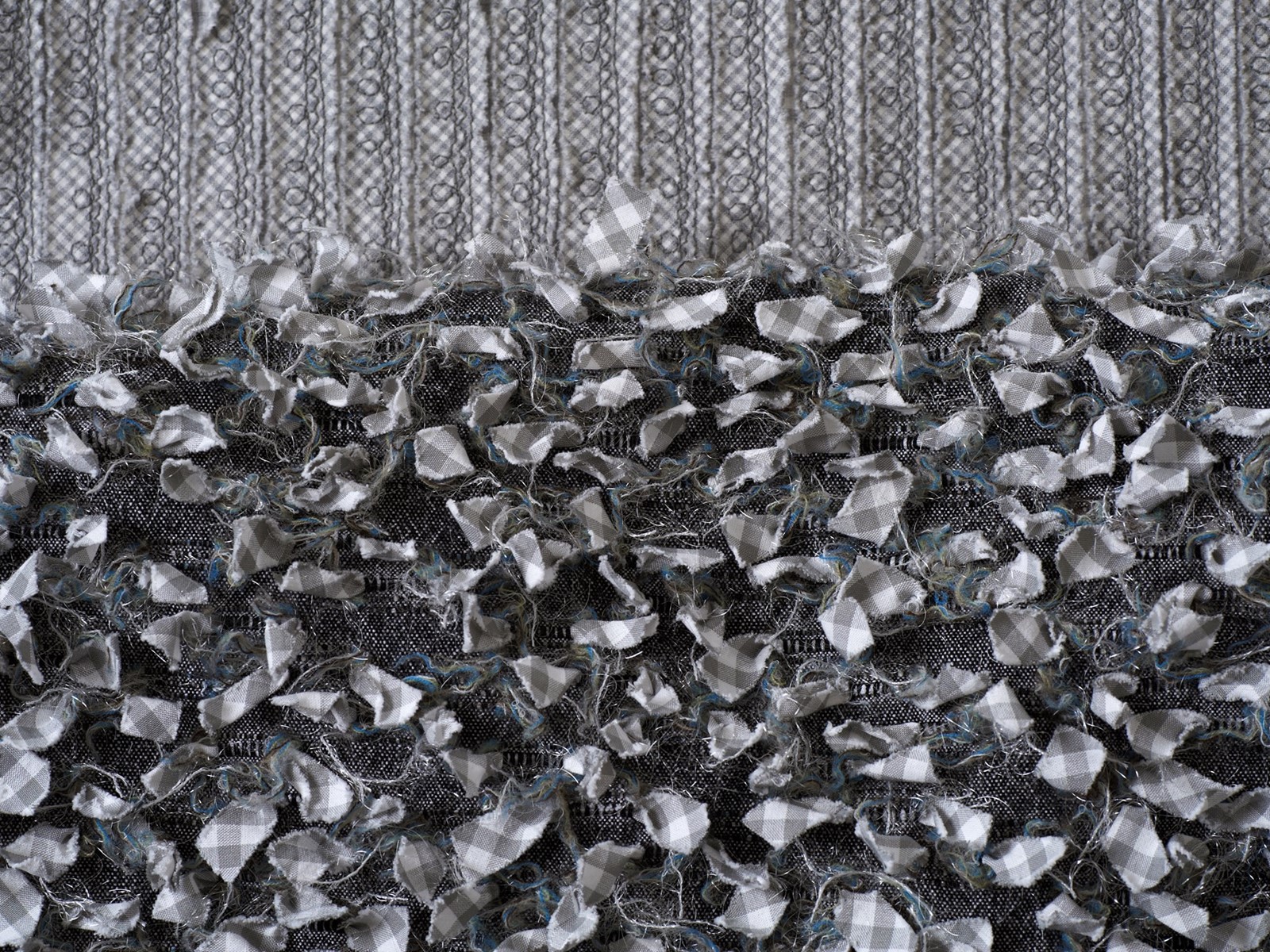

On S/S16's Air Flower...

"For S/S16, I did my first collaboration; I worked with a young Japanese artist, Yamamoto Katsuhito, who uses color pencils in his creations, which was expressed with a multicoloured jacquard weave. For the base, cupra yarn is used for the warp, and a soft touch stretch yarn is used for the weft. By using thick cotton yarn for the weft, the flower patterns look almost three-dimensional and float upwards. The leftover weft yarn used for the flower pattern is then cut. For the cut jacquard we can use both the front-side, that is flat, and the back-side, which is cut and shaggy."